Joinery is the art of joining timbers with wood connections. The precise mortise & tenon joinery used in our post & beam buildings is the result of crafting every timber with our state of the art CNC machines.

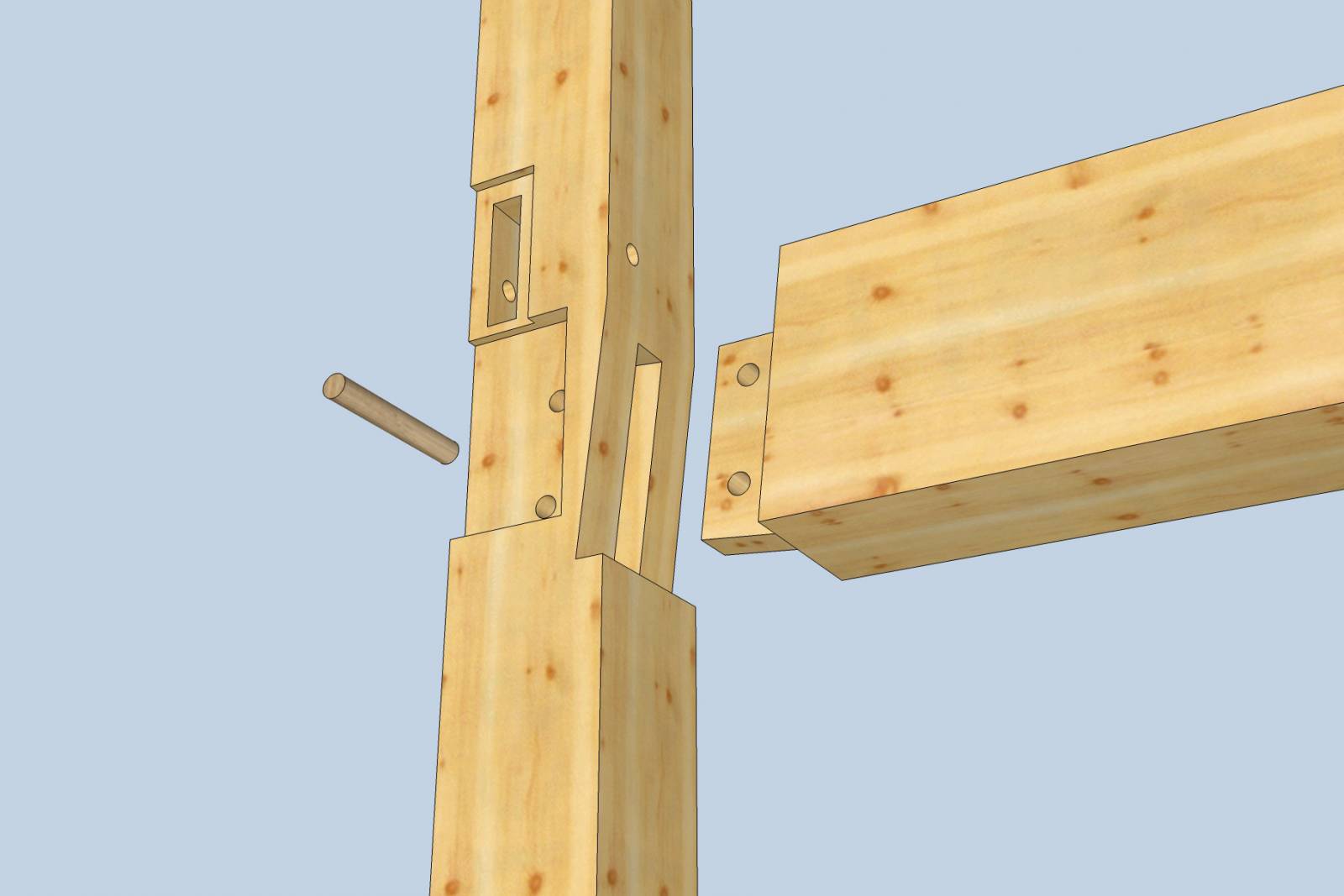

Mortise and Tenon Joinery

Mortise & Tenon is the fundamental joint in all timber framing. Other joinery is generally a variation of the mortise & tenon. With mortise & tenon joinery, the mortise pocket accepts the tenon tongue and is secured with an oak peg. For added strength, we house all of our mortise & tenon joints so that the weight is not only bearing on the tenon, but on the post as well.

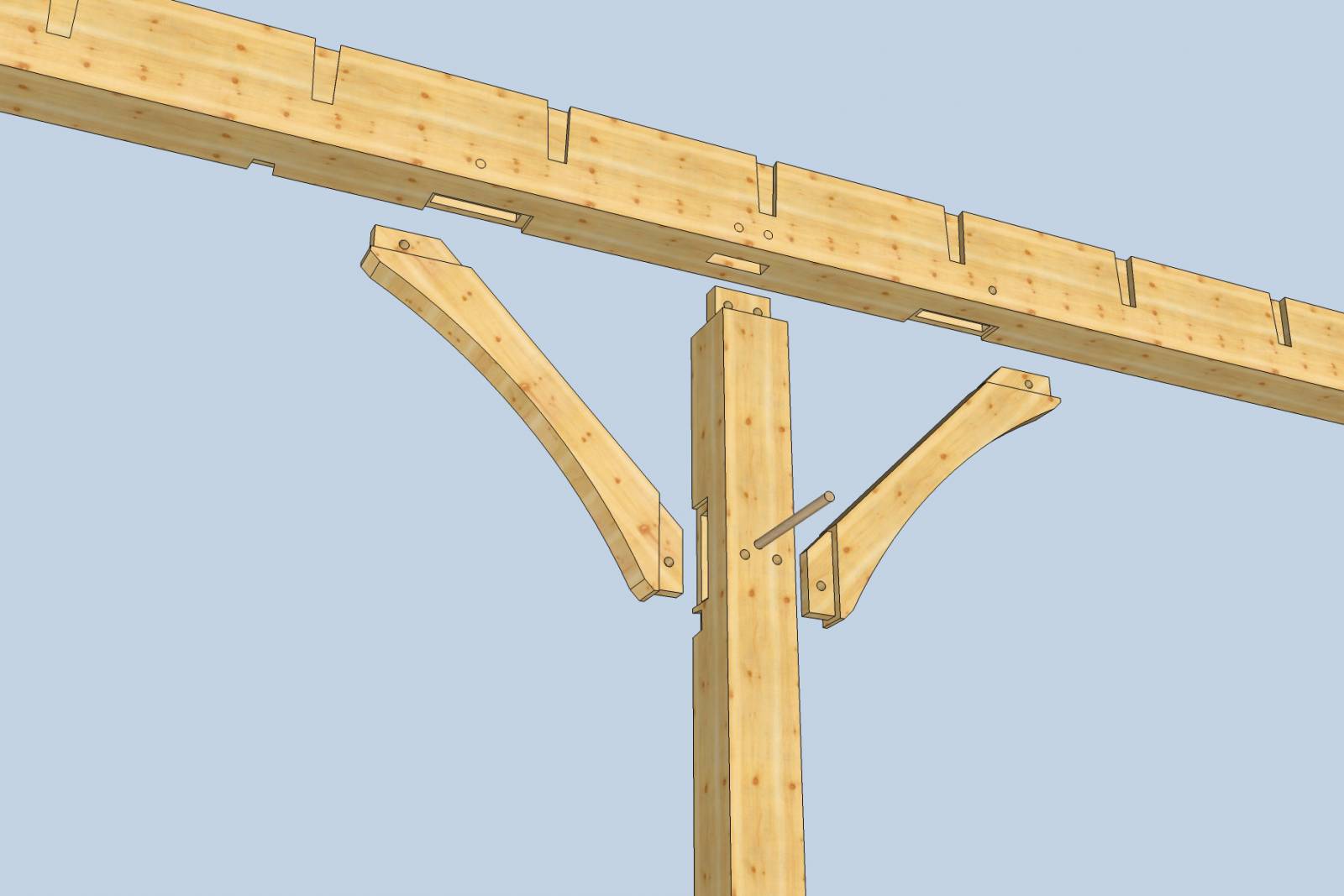

Kneebrace Joinery

The strongest geometric shape in engineering is the triangle. Kneebrace joinery creates a triangle where the post meets the beam. This provides rigidity to the frame, and is one of the reasons why timber frames are so strong. Therefore, kneebrace joinery is critical to the timber frame as it creates a self-supporting structure to resist wind loading. We arch all of our kneebraces as part of our signature style.

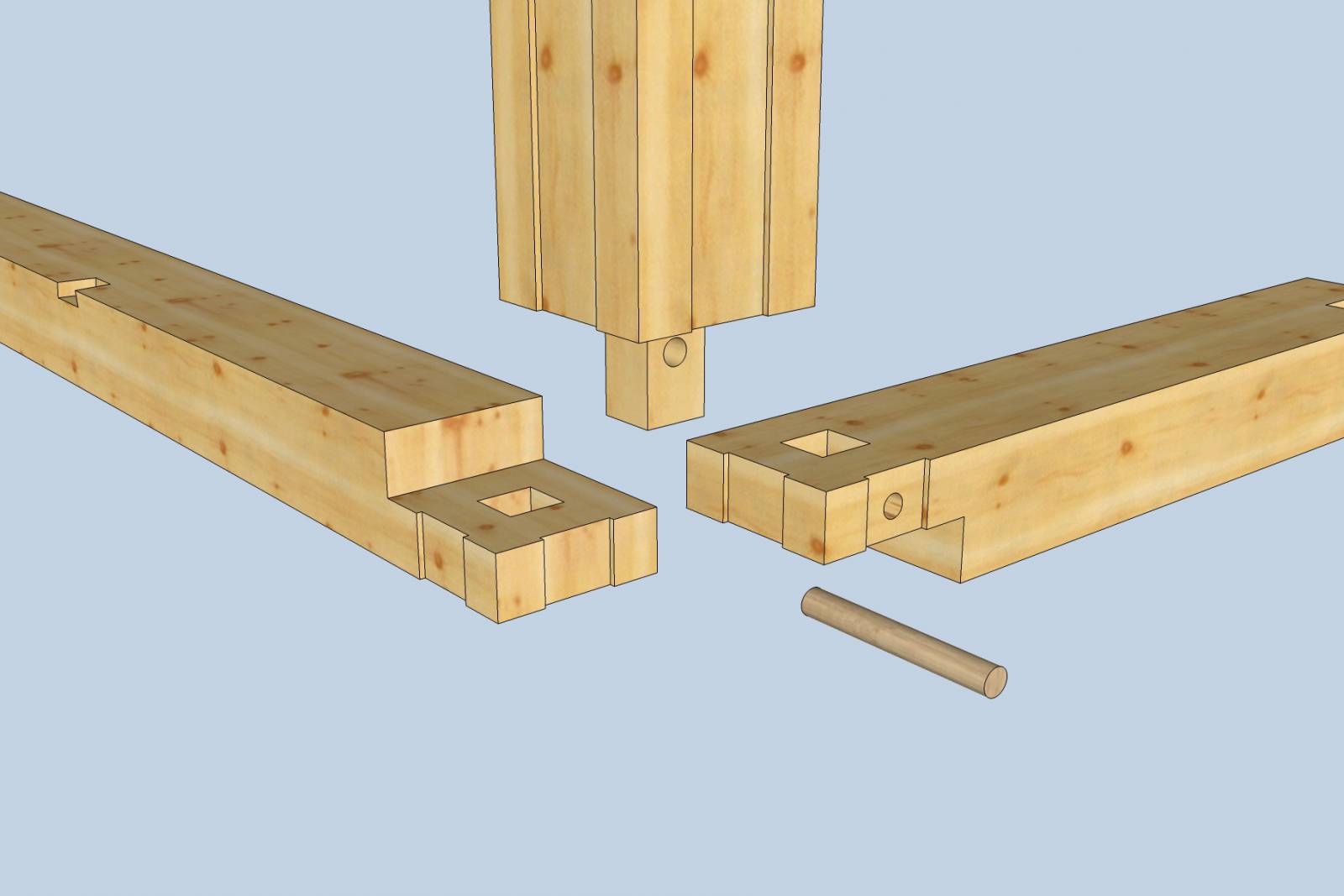

Timber Sill Joinery

Barns built in the 1800s often had a simple stone foundation above the frost line. Early craftsmen would lay heavy timber sills over the stone and build up the frame from there. The timber sills helped tie the structure together over the course of the stone foundation’s seasonal movement. Even though we use a concrete frost wall foundation nowadays with footings well below the frost line, we still employ a heavy 6x8 timber sill under all our barns. This has the benefit of added strength and of course authenticity.

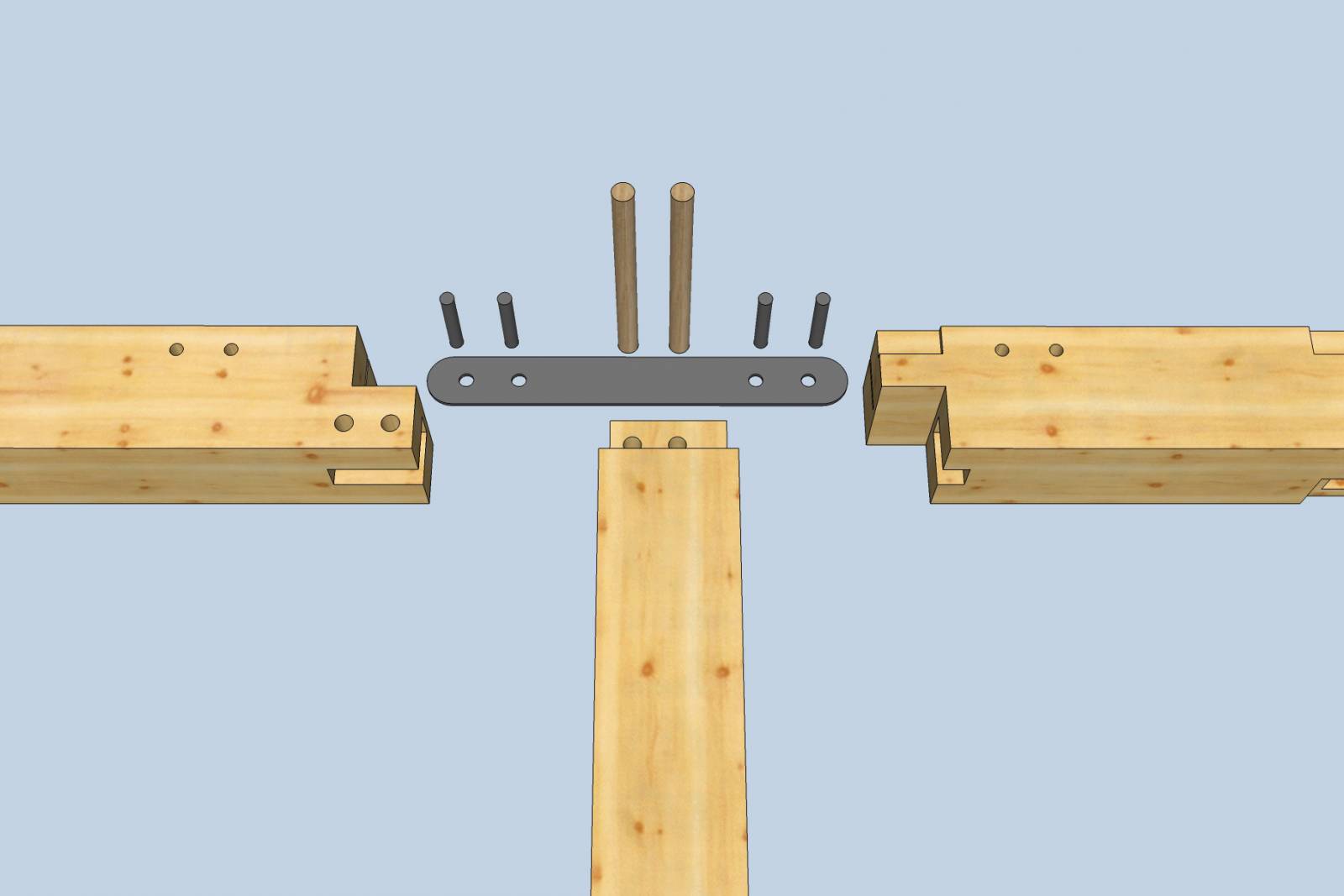

Half Lapped Scarf Joinery

This joinery serves to join timbers together to create a longer beam. It is carefully engineered to resist tension, compression, and shear forces. At The Barn Yard, we reinforce our half-lapped scarf joints with a concealed steel plate and steel pins. This makes the joint many times stronger than if it were a wood-only connection. In the end, the steel is completely hidden by oak pegs.

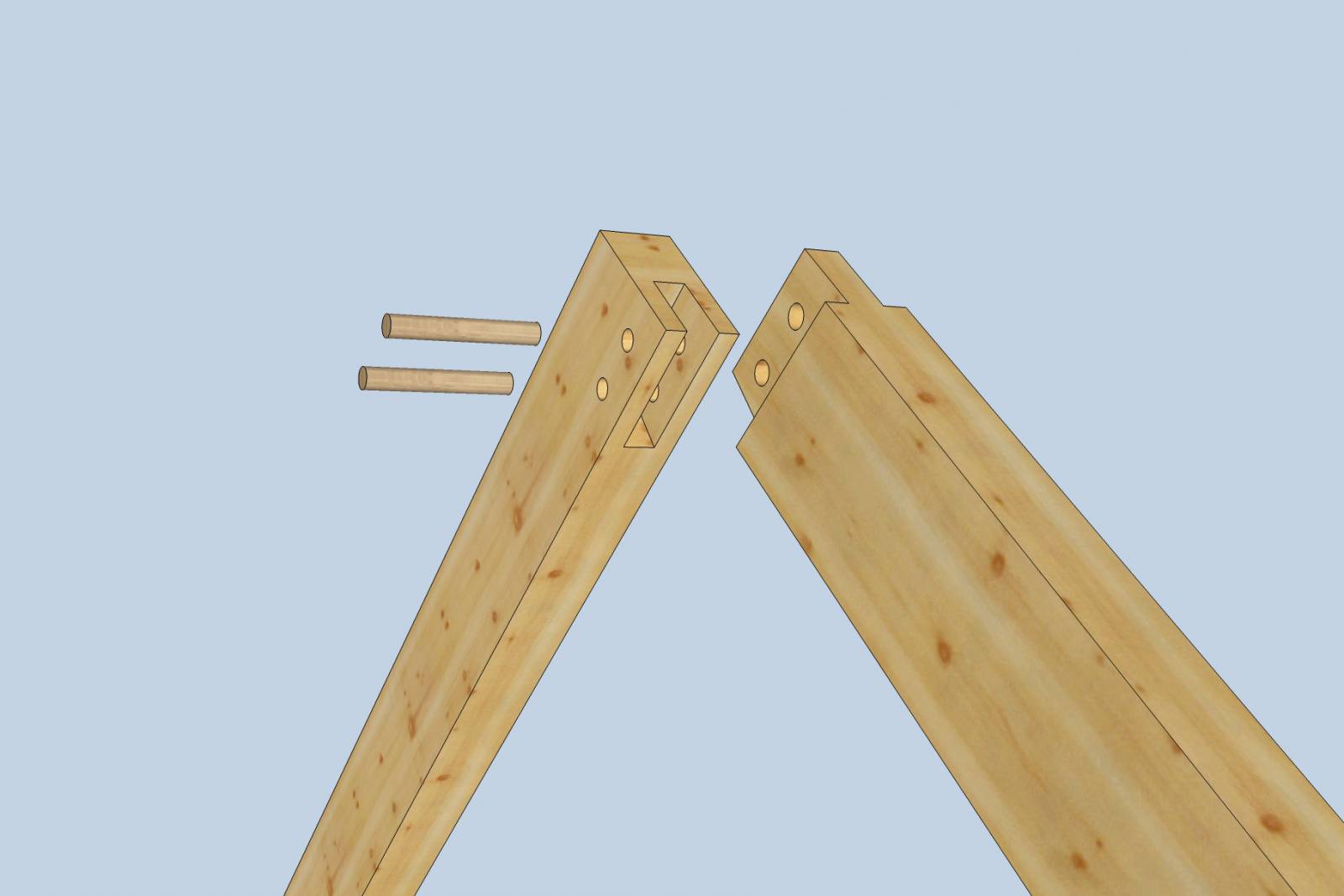

Tongue and Fork Joinery

By employing this type of joinery, early Americans were able to join timber rafters so well that a ridge pole was no longer necessary. Our tongue & fork rafter peak connection is extremely precise and strong. In addition, we use 4x10 timber rafters for an extra-strong roof system.

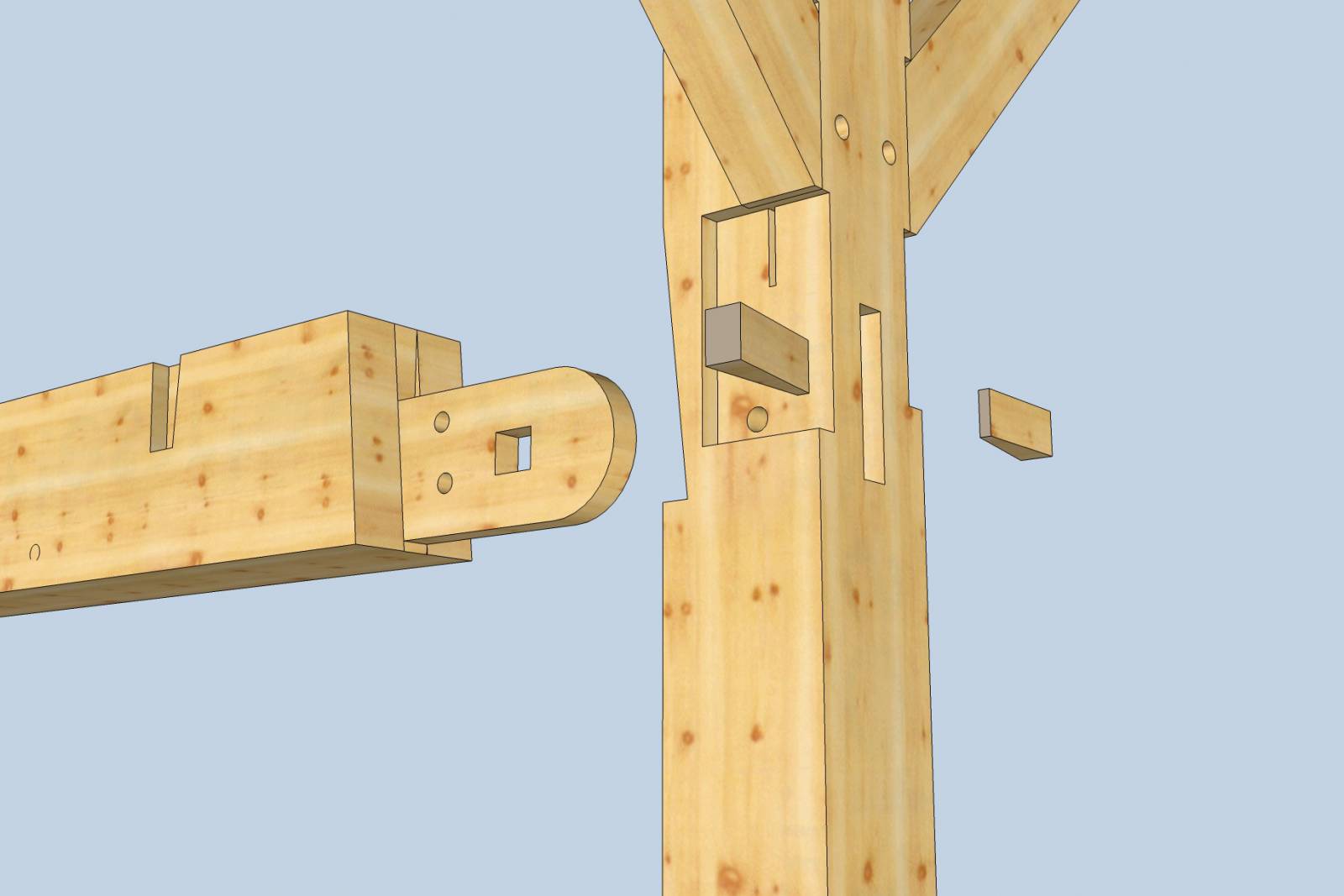

Wedged Anchorbeam Tenon Joinery

The wedged anchorbeam tenon is designed to resist the outward thrust cast on the principal posts and anchorbeam by the roof system. The anchorbeam is carved out to create a through tenon, which passes through a mortise and is tightly secured with two oak wedges. Wedges are used in conjunction with pegs in this joinery because wedges are able to draw the joint together tighter. We round the end of the wedged anchorbeam tenon for a nice smooth appeal.

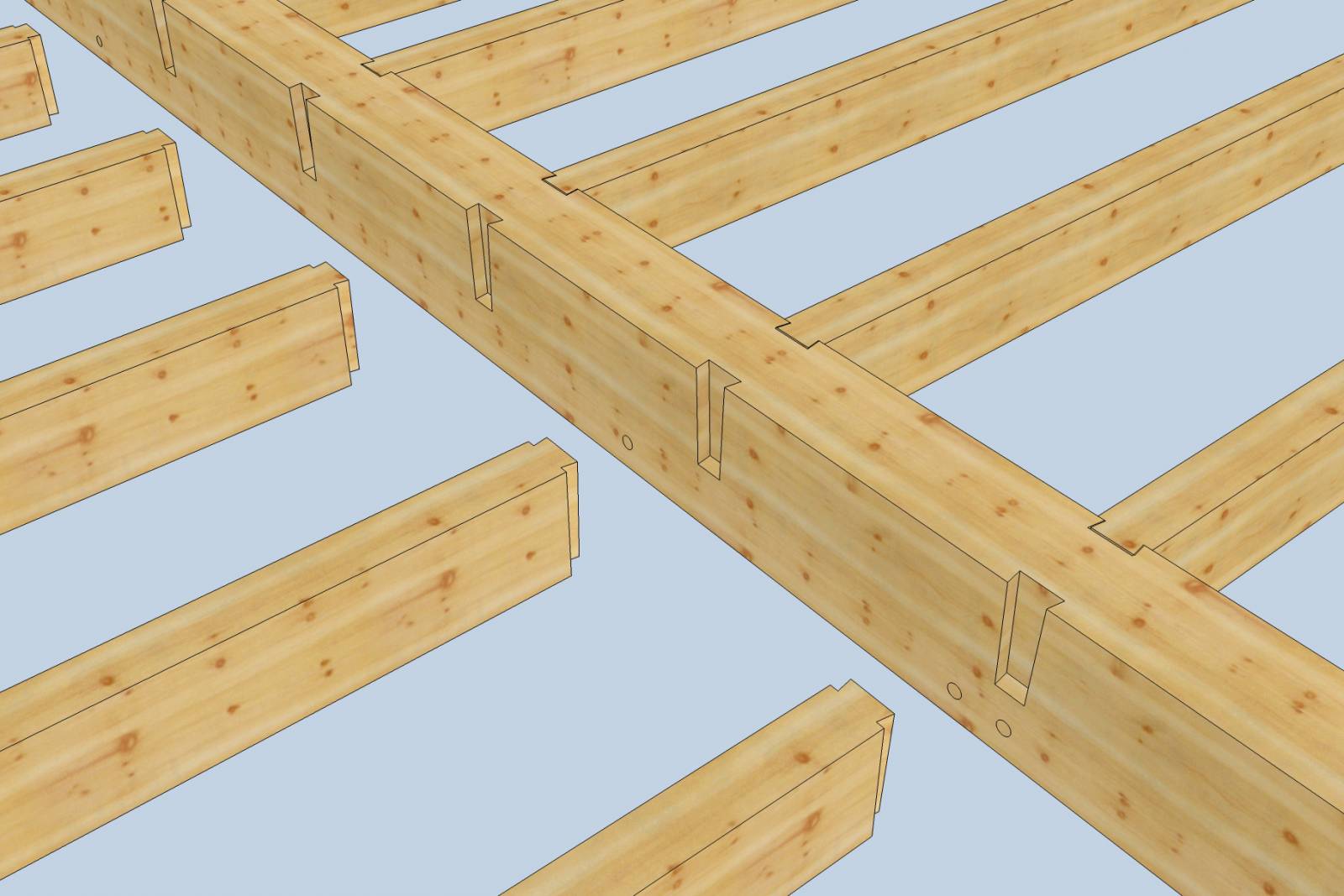

Dovetail Joinery

The floor joists of 1800s barns often rested on top of the beams. Instead, we dovetail the floor joists so they sit flush with the top of the beams. What this does, besides adding character, beauty, & strength, is allow for more upstairs headroom. Wall purlins, to which the siding is secured, are also dovetailed into the posts for a clean, flush look with no visible fasteners.

Shop Tour

Join Everett Skinner IV for an in-depth educational tour of our advanced timber frame design & manufacturing facility in Ellington, CT. Start in the design department and then head into the shop. See our CNC machines in action with sawdust flying and timber frame joinery being crafted with precision, then hand finished, ensuring the highest quality, most authentic timber frame barns & kits available today. Learn all about joinery—the art of connecting timbers with only wood to wood connections—and why we’re blending modern technology with old-time tradition to bring new life to this lost art. Discover the difference between post & beam and timber frame. And see what makes our timber frame kits the best.